Ready Mix Concrete Supplier

Ready Mix Concrete Supplier

We Are One Enterprises is well established and specialized in the supply of ready mix concrete supplier to its clients in the market. The company is among the best ready mix concrete supplier that strives to deliver quality products and services to its clients. This reputation acquired by We Are One Enterprises ready mix concrete supplier is established from many years of experience and understanding of the construction industry. This reliable ready mix concrete Supplier in india makes sure that the concrete is mixed and prepared based on certain measurements to achieve strength and sturdiness for any construction project. Any customer seeking a reliable ready mix concrete supplier should choose We Are One Enterprises for quality and prompt delivery services. This shows that the company has earned the reputation of being a preferred ready mix concrete supplier through its commitment to quality and innovation.

Key Features of Ready Mix Concrete

⦁ Best solution for Mass Concreting.

⦁ Concreting in congested areas is possible through RMC.

⦁ In the basement and raft below ground level, specialized concrete can be provided through RMC.

⦁ RCC members with heavy and congested reinforcement can be concreted through RMC.

What is Ready Mix Concrete?

Concrete that is provided ready to use is known as ready mixed concrete (RMC).

RMC is described by the American Concrete Institute’s Committee 116R-90 as: “Concrete that is manufactured for delivery to a purchaser in a plastic and unhardened form”.RMC is described as “Concrete mixed in a stationary mixer in a central batching and mixing plant or in a truck-mixer and given in fresh condition to the purchaser either at the site or into the purchaser’s vehicles” by Indian Standard Specification IS 4926:2003.

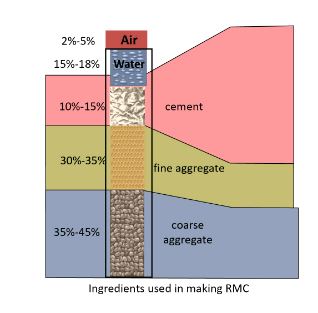

India has a long history of producing concrete on-site using rudimentary tools and a big labor force. An innovative technique, ready mixed concrete uses a lot of automation and mechanization. A typical RMC facility includes weigh batchers for weighing out the various components of concrete, silos and bins for storing cement and aggregates, high efficiency mixers for thoroughly mixing the ingredients, and a computerized system for managing the entire production process. The finished concrete is of a substantially higher caliber than site-mixed concrete.

Why Choose Ready Mix Concrete?

- Convenience: Instead of doing it, let’s say goodbye to those days where you had to manually mix concrete on the spot. You can relieve yourself of the hassles and fraggles of the conventional mixing methods of concrete with regard to RMC. Just place an order, use any beverage of your choice, and get ready for the cleanup.

- Quality Assurance: All of our RMC samples were subjected to high-level market testing and satisfied the main requirement, durability and strength. As you can believe that every batch is made with special care to the concrete performance criteria which mean the construction lasts a bit longer.

- Cost-Effective: Even premises RMC presumably being a top-shelf expenses, it eventually will save your precious penny in future. Hence, RMC can be considered as an economical method of concrete making regarding wastage not being frittered, labor cost reduction and very small construction time.

- Versatility: RMC is the ideal choice for building a skyscraper or a simple house. It can perform all of the tasks that are required of it. By available to you as per your specifications, which could be for domestic, commercial or industrial purposes, you can fine-tune the concrete mix designs.

- Environmental Friendly: RMC possesses less environmental effect versus the traditional method of concrete mixes. Your project is based upon the basic principles of waste reduction and emissions, and that thereby promotes greener practices by construction.

How Does It Work?

Using Ready Mix Concrete is as easy as 1-2-3:

Order: Please place an order with the quantity and mix design you require as the specifications.

Delivery: We deliver the exact amount of RMC needed at your site at the exact moment you need it.

Pour: After delivery, RMC can be used immediately. You can pour it into any form you would like and lightly vibrate it. Mixing is eliminated as well as mess—leaving only that which is fine: speed and unparalleled quality.

Our Commitment to Quality

Developing Special Mixes is what we do the best. The Ready Mix Concrete from We are one enterprises is a perfect fit for you. To give you the peace of mind, our batching plants are equipped with modern equipment, qualified technicians, with quality being our uncompromising guiding principle, we make sure that every batch of RMC will not only meet your requirements but also surpass them.

Get Started Today

Are you all set to get a first-hand feel of the comforting, efficiency, and quality of concrete Ready Mix? Reach out to us now and let’s talk about your project need, and our mission is to conduct a good job and make your business develop steadily, step by step.

Brand Associated