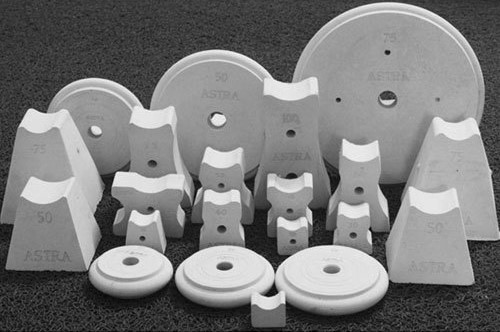

Cover Blocks

Key Features

- Cover Blocks help maintain proper cover to the reinforcement bars.

- cover blocks provides protection from the external environment to rebar against corrosion.

- cover blocks ensures an adequate bond area so that stresses from concrete are transferred to steel.

- cover blocks delays softening of rebars due to high temperature in case of fire.

Strength – A minimum compressive strength of 60 MPa. There is therefore no deformation when exposed to heat, cold, or being underweight before and during concentrating.

Durability – According to rigorous international tests, Cover Blocks have over 100 years of life and very little chloride penetration, giving structures a high degree of durability.

Precision – Covers Blocks guarantee accurate measurements well within allowed tolerances.

Easy Identification – Every piece has the cover block’s size engraved on it (in both metric and imperial units), removing any room for error.

Compatibility – Concrete bond is perfect.Between the cover blocks and the surrounding concrete, no hair cracks are forming.

Quality – Manufactured in accordance with ISO 9001:2015 ( Certified by TUV SUD under registration no. 99100 11214) Conform to British standard H BS 7973-1:2001

Low Permeability – Tests on cover blocks indicate low water and chloride ion penetration.

Leed Credit – Under category MR credit 4 for recycled building materials in LEED for new construction, builders may add cover blocks.

Application

When compaction is impossible and access is restricted, non-shrink micro-concrete can be utilized to increase the load bearing capacity of RCC columns by jacketing. This can be done to repair or restore damaged RCC elements like beams, columns, etc.

It has been created and engineered for use in medium- and large-scale repairs and restorations with typical thickness ranges of 5 to 100 mm.

The layers that must be put to this product typically range in thickness from 5mm to 25mm. Depending on the type of repair, the location, the quantity of exposed rebars, and the final formulation of the product created for the customer, greater thickness is also possible.

Benefits

⦁ Consistent performance is assured since the product is formulated, designed and manufactured in the factory controlled environment.

⦁ High initial strength and sustained long term performance and strength.

⦁ This product is Dual Shrinkage Compensated to reduce the risk of cracking.

⦁ Self-flowing and Free Flowing (hence does not require any additional compaction).

⦁ Extremely low permeability to provide maximum protection to the embedded steel reinforcement.

⦁ Strength and Durability Designed to match the parent substrate.

Uses

⦁ Dense reinforcement area where conventional concreting is very difficult.

⦁ For Repairs or Restoration or Rehabilitations or Jacketing of tight/congested RCC Reinforcement.

Method of Application

1.Clean the surface and remove loose concrete, dust, oil, paint, grease, waterproof coating etc.

2. Expose any corroded steel in the repair area and remove all scale and corrosion deposits. Apply Rust Remover for rust free bars.

3. For Cathodic Protection, apply Epoxy Zinc Primer over the cleaned re-bars and allow it to dry before pouring of Non-Shrink Micro Concrete.

4. Saturate the substrate with water to prevent absorption of water from the mixed material.

5. Add around 80% to 85% of the predefined amount of water in the mixing vessel. Start addition of micro concrete powder slowly under continuous mixing, preferably in a paddle mixer or a slow speed mixer. Keep mixing for 2 minutes. Add a balanced quantity of 15%-20% of mixing water and again mix for another 2-3 minutes to form a homogeneous, free flowing uniform and lump-free mix. Allow the mix to rest for 2-3 minutes and then remix for a minute or two before applying.

6. Shuttering has to be water tight to avoid any material loss and abnormal shrinkage or honeycombing.

7. Start the pour immediately and use the material within 20 minutes of mixing. Remove the shuttering preferably after 24-48 hours (depending on weather conditions).

8. Cure the repaired concrete for a minimum 7 days or use a high quality curing compound for curing.

Brand Associated