Slag Sand

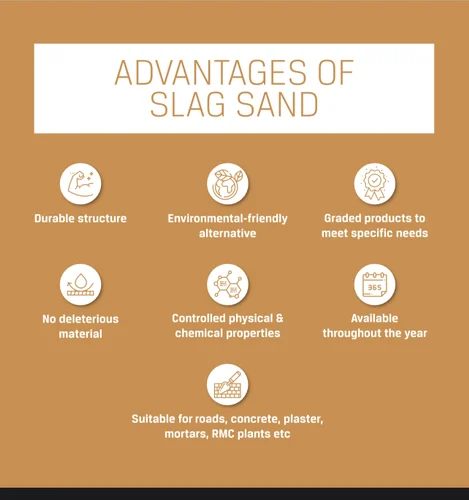

- A non-metallic product, consisting of glass containing silicates and alumina silicates of lime, is a byproduct of metal smelting process, produced under controlled condition.it does not contain any materials that may affect the strength and durability of concrete, such as chlorides, organic matter, slit and shells.

- Screened slag is superior to river sand because the river sand/crushed rock fines contain fossils and other irregular particles, such as clay and silt, that affect quality and durability. Our Screened Slag meets all the requirements of IS:383-2015.

- Sand is the backbone of the construction industry and has become a problematic resource to procure in India. Availability and inferior quality have both contributed to the price volatility resulting in illegal mining by the sand mafias. river sand is controlled by the government in many southern states.

- Sand plays a vital role in enhancing the strength. Setting and bulking of the concrete & mortar. It is a perfect raw material that is easy to find and an excellent matrix to fill in pores. Perfectly filling of pores is important as it helps in increasing the density of the structure thus improving the strength and durability.

Comparison between River Sand & Slag Sand

- Slag density is 30% lesser than river sand, hence gives 30 % extra volume per ton, which in turn reduces the per brass cost of sand.

- Zero Silt in JSW slag sand v/s In river sand, 7-8% of silt even after washing two times.

- Maximum moisture in JSW sand is 10 % v/s moisture in river sand is 15-20 %.