block jointing mortar

Block Jointing Mortar

Key Features Of Block Jointing Mortar

- High Strength with Thinner Joints (3mm thin).

- Faster Construction as no Curing is required.

- Reduces Wastage.

- Economical.

- Technologically Superior and Consistent in Quality.

- No water percolation.

What is Block Jointing Mortar ?

Block jointing mortar, which is also named block adhesive or masonry adhesive, is a type of mortar that is used in construction to join concrete blocks, bricks, or stones into one single structure to build walls or other structures. Difference of the block jointing mortar to the normal mortar mixes is that it is usually the pre-mixed one and then used without adding the water or mixing at the site of the construction that gives the time and effort savings.

Benefits of Block Jointing Mortar:

![]() High Strength: It’s superbond technology and use of selected graded ingredients makes the adhesion stronger to surface.

High Strength: It’s superbond technology and use of selected graded ingredients makes the adhesion stronger to surface.

![]() Reduces Wastage: It has excellent workability compared to conventional mortar.

Reduces Wastage: It has excellent workability compared to conventional mortar.

![]() No water Percolation: due to it’s thinner joints and materials used no pores and formed to let water pass.

No water Percolation: due to it’s thinner joints and materials used no pores and formed to let water pass.

![]() Faster Construction: No curing time is required and hence making the construction faster than conventional mortar.

Faster Construction: No curing time is required and hence making the construction faster than conventional mortar.

![]() Economical: It’s ease of application saves time and cost.

Economical: It’s ease of application saves time and cost.

![]() No heating: The 3mm thin joints and the materials used to prevent heat loss via the joints.

No heating: The 3mm thin joints and the materials used to prevent heat loss via the joints.

![]() Superbond Technology: It contains selected graded ingredients and imported & modified polymers for stronger adhesion and smoother finish.

Superbond Technology: It contains selected graded ingredients and imported & modified polymers for stronger adhesion and smoother finish.

Technical Specifications

Parameters | Test Method | Specification |

Appearance | Visual | Free Flowing Powder |

Colour | Visual | Greyare |

Open Time | EN 1346 | 10-15 min |

Mixing Ratio | By volume | 3:1 (Powder to water) |

Pot Life | In-House | >90 min @ 27 deg C |

Self Curing | - | Yes, No water curing is required |

Hard Dry | - | 24 hrs |

Tensile Adhesion (28 Days) | DIN EN 1015-12 | >0.5 N/mm2 |

Compressive Strength (28 Days) | DIN EN 1015-11 | > 12 Mpa |

Surface Preparation and Precaution:

- Masonry Surface should be clean, without dust and voids. Pre-wet the blocks prior to the application of Jointing Mortar

- Block Jointing Mortar contains only eco–friendly, fillers and additives. However, being sand and cement

based it is alkaline and hence it is advisable to avoid direct eye and skin contact with this. In case of eye contact, wash

with clean water at least for 15 minutes and seek medical help. - Always add Block Jointing Mortar to water and not water to Block Jointing Mortar during

mixing

Packaging & Storage:

- Block Jointing Mortar is available in 40 Kg bag and has a shelf life of 6 months subject to

proper storage in cool dry place. - As temperature, humidity and other parameters vary from site to site. The above information should be

treated as a general guideline

Water Demand:

- Depending upon the substrate and climate approx. 10 to 12 litre of water for 40 Kg bag. For concrete blocks,

wet mortar should have less water to form 2 to 3 mm bed of Block Jointing Mortar.

Coverage:

- Coverage of Block Jointing Mortar is approx. 120 to 140 sq.ft. of block size 600x200x100mm in 40 kg

bag. The coverage area however will depend upon the quality and evenness of the substrate, thickness of joints

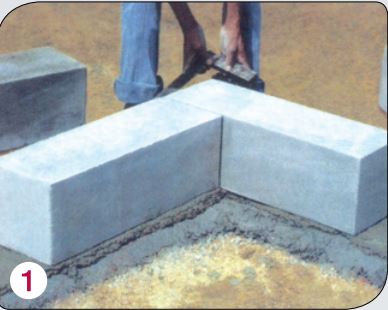

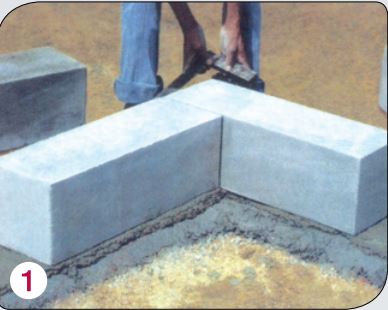

Easy Application for Faster Construction:

ConventionalMortar used for laying the first course of blocks.

In 10 - 12 | of water, add 40kgs of Block Jointing Mortar. Stir mix continuously for 5 - 10 mins by using electric mixer or by hand to obtain homogeneous lump-free mix.

Allow the Resultant Wet Mortar to stand for 5mins for the additive to dissolve. Use the mix within 20-30 mins for best results.

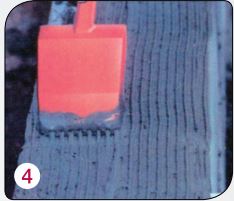

For better coverage, it is advisable to use notch trowel of 3-4 mm, to have good contact and stronger bonding

For better coverage, it is advisable to use notch trowel of 3-4 mm, to have good contact and stronger bonding

Scrapping to ensure uniformity for Block Jointing Mortar application.

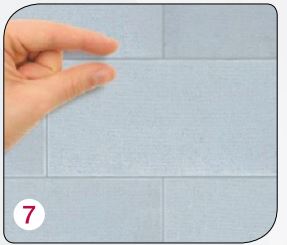

Superbond Technology ensures high strength Thinner Joints.

For better coverage, it is advisable to use notch trowel of 3-4 mm, to have good contact and stronger bonding

Brand Associated